At a glance

Product information

take your print inspection to the next level

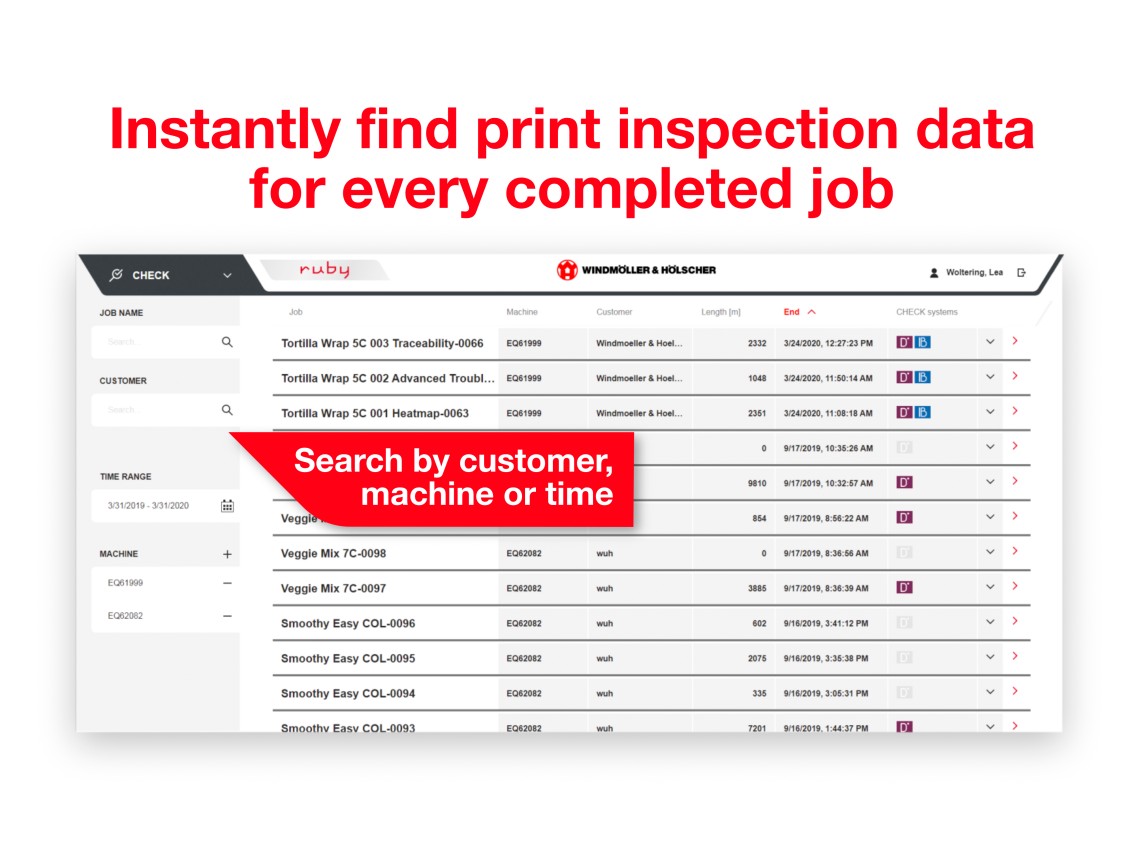

With the extension RUBY Check, you can view, analyze and process the inspection results of all connected printing presses centrally in the office. This ensures a consistently high print quality.

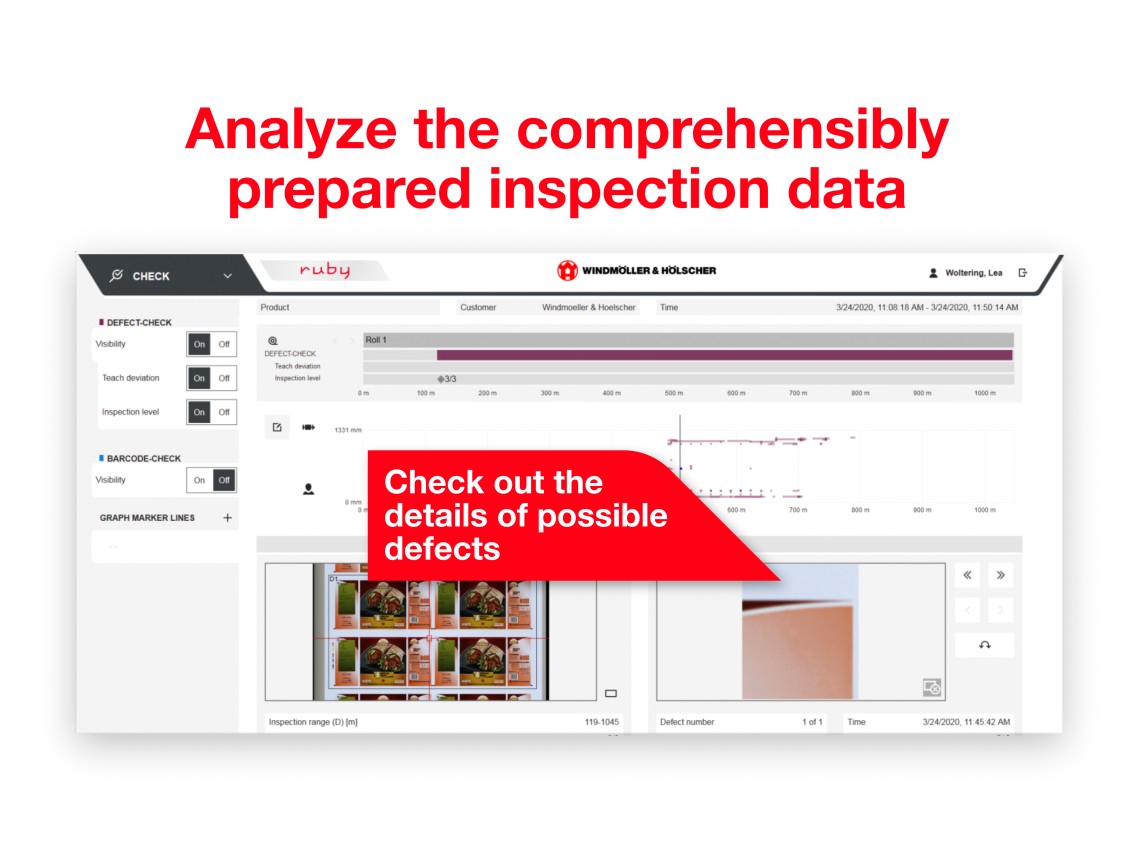

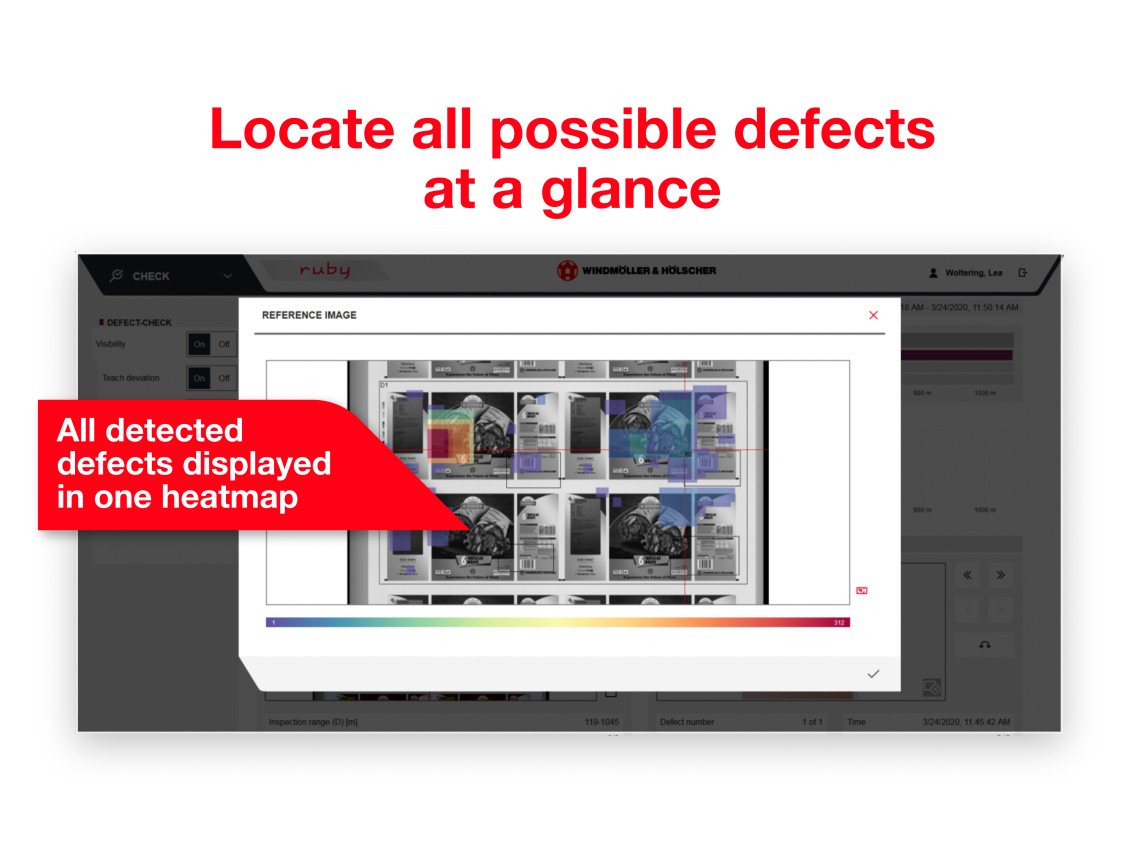

You decide in the office which printing defects are significant and which parts of the order become waste. The intuitive interface and effective tools enable you to work efficiently and time-saving. Our unique heat map gives you a quick overview of the number and position of defects in the printing image. RUBY Check knows the machine: Display all process parameters for the printing defect to analyze defect causes and optimize the process.

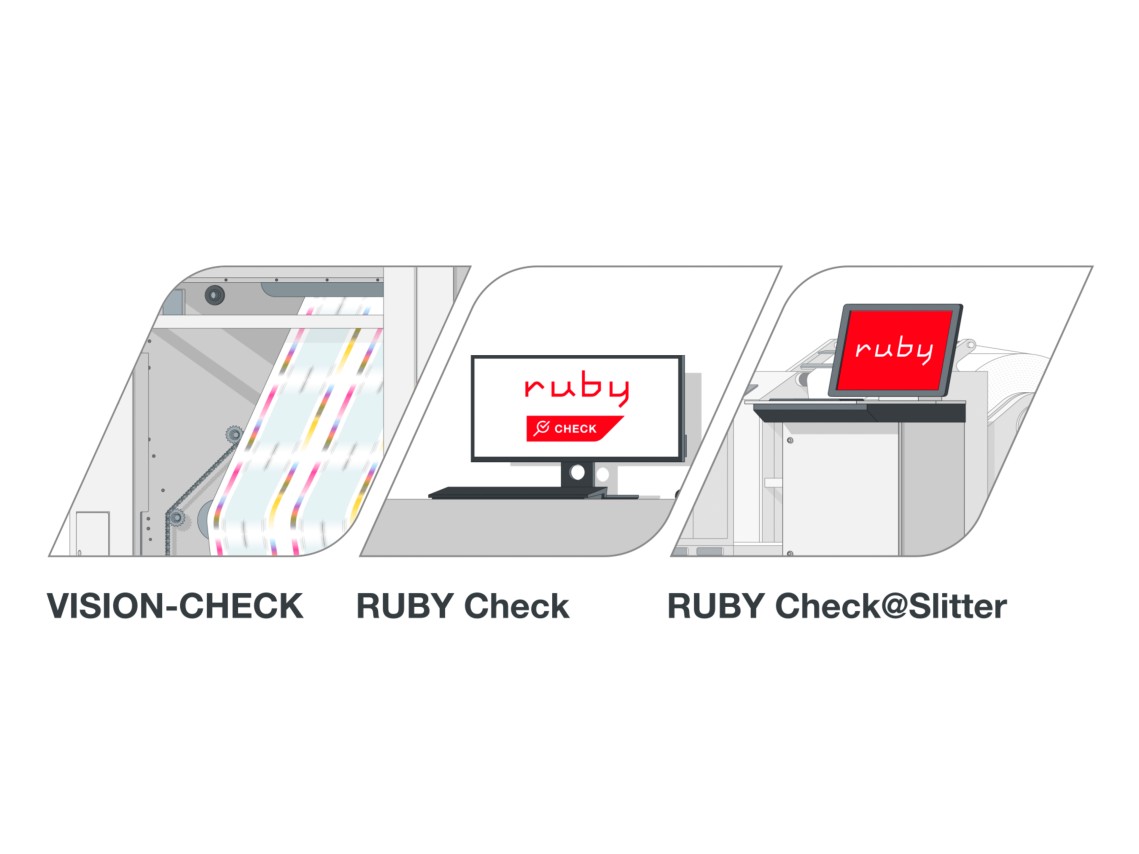

Integrate downstream process steps for efficient and time-saving further processing into your RUBY workflow:

RUBY Check@Slitter locates print defects on the slitter or rewinder fully automatically. The roll to be processed is auto-matically identified in your downstream converting machine. The inspection data is called up and the converting machine will be stopped at the correct position fully automatically.

For all W&H printing presses equipped with the VISION CHECK inspection system.

Use cases with RUBY Check

1. Traceability and Claim Management

- Guarantees complete traceability of the inspection data for at least 1 year.

- Detailed roll- and job reports.

2. Remote Quality Assessment

- Leave quality control to quality managers

- Review, analyse and process your print inspection data remotely for increased production efficiency and print quality

- Find all possible defects at a glance with our defect heatmap for highly efficient assessment of your inspection data

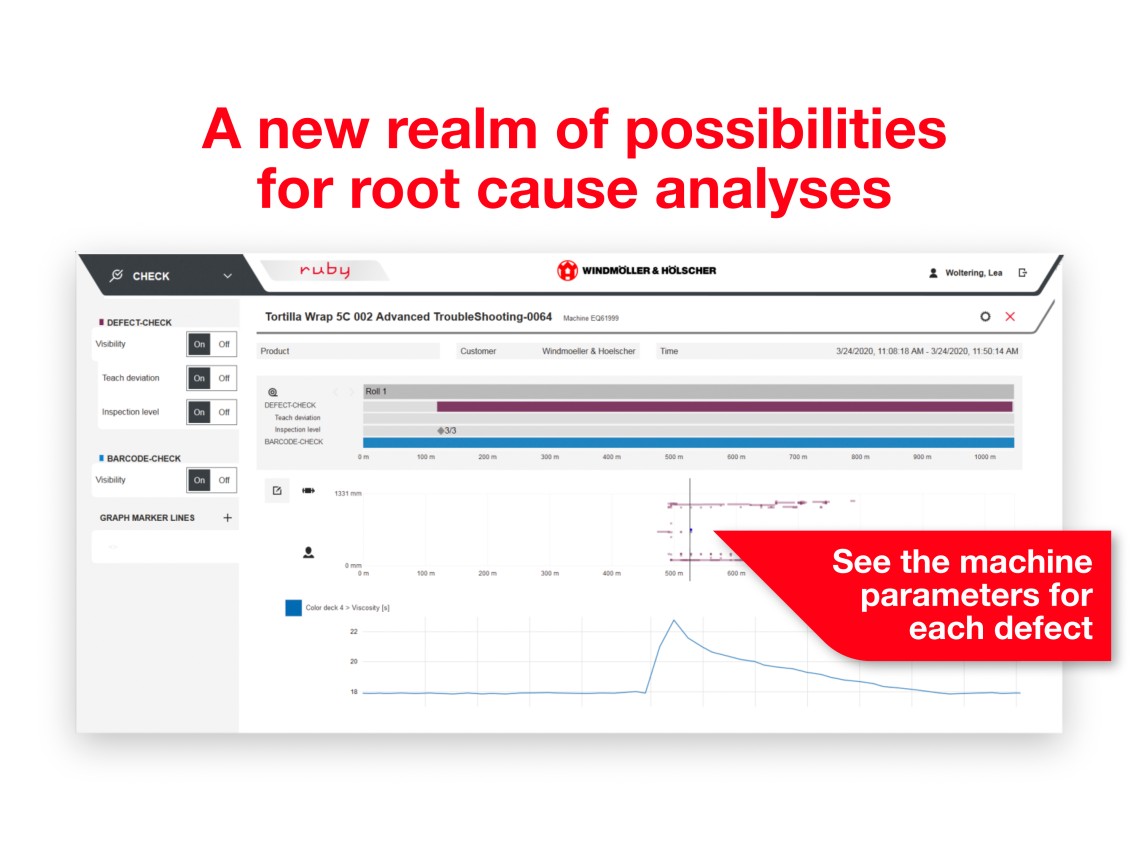

3. Root Cause Analysis

- RUBY Check is fully integrated into the W&H world

- Overlay machine parameter trending and print inspection data for root cause analysis

- Optimize your processes and become more efficient

4. Downstream Processing with RUBY Check

Speed up your Downstream Processing with RUBY Check

Optimize your end-to-end workflow to reuse defect detection data from the printing machine. Use the W&H’s new Inkjet Marking System integrated in your printing press to mark your jobs for safe position tracking of defects by means of meter markings, completely independent of a starting position.

W&H’s print inspection system VISION CHECK detects print defects, which you can assess conveniently from your office with RUBY Check. Define waste areas which should be removed.

With RUBY Check@Slitter you can locate this print defects easily in further process steps (slitter, rewinder…) fully automatically. The Mark Reader positioned in your processing machine identifies the job and the job position based on the inkjet marking. The processed data is automatically called up and displayed at the RUBY Check Terminal on the processing machine. RUBY Check@Slitter controls the processing machine and stops at the correct position automatically to the desired position (if supported by manufacturer) for efficient and time-saving processing.

Download

"Thanks to RUBY we can review and evaluate machine settings afterwards. We define causes of defects and avoid them in following orders."

Marco Kleemann, Manager Flexoprinting, NEEMANN LiteFlexPACKAGING