Windmöller & Hölscher Concludes a Successful drupa and EXPO, Highlighting the ALPHAFLEX Flexo Press and Personal Connections

After exhibiting at drupa 2024 and hosting an In-house EXPO at company headquarters in Lengerich, Windmöller & Hölscher reports positive results. For 11 days, the latest developments and innovations in printing technology for the flexible packaging industry were prominently showcased.

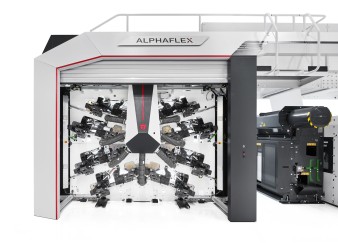

The all-new ALPHAFLEX CI flexo printing press was the highlight of the W&H stand at drupa.

“For W&H, the focus at drupa 2024 was on personal connections and relationships. We are delighted with the high quality of the discussions we had with experts from all over the world. It was great that the industry was able to meet in Düsseldorf again after 8 years”, says Dr. Sascha Witt, W&H's Chief Sales Officer.

The ALPHAFLEX flexo press celebrates its world premiere

The W&H booth featured the world premiere of the ALPHAFLEX CI flexo press. A live show on the machine was presented several times each day. “The ALPHAFLEX is the latest addition to our flexo press portfolio. It is focused on the core requirements of our customers and is designed for high-quality printing on flexible packaging materials. Featuring eight print decks with W&H’s latest technology, the press runs jobs with excellent print quality at a consistent speed of up to 400 m/min. It combines superior efficiency and consistent performance, making it ideal for producing modern packaging solutions“, says Dr. Falco Paepenmüller, W&H CEO.

Co-exhibitor GARANT MASCHINEN, a subsidiary specializing in machinery for paper packaging, presented the MATADOR e.BAG, an e-commerce mailer bag machine. “The live demonstration of this machine from the e.BAG series highlighted environmentally-friendly paper shipping and return mailer bags for the e-commerce market. “We had many interested visitors and further discussions”," says Torsten Berding, Managing Director of GARANT.

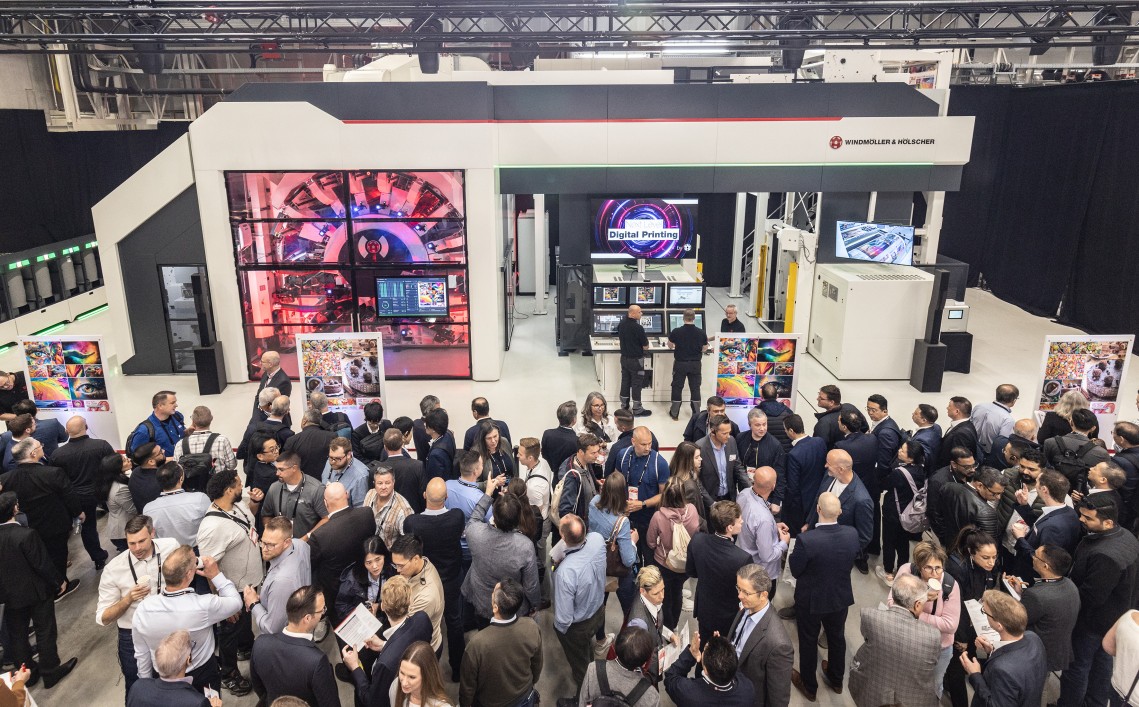

A highlight in Lengerich: The new digital printing concept attracted many visitors.

Live machine demonstrations in Lengerich

During drupa, W&H also opened the doors of its technology centre to visitors on four days. In the 10,000 square metre technology centre, visitors were able to experience machines for the extrusion, printing and processing of flexible packaging. W&H showcased live demonstrations of 10 machines each day. “Our technology centre is unique in our market in terms of its size and range of machines. This is particularly attractive for many customers, as they can also produce several work steps and see them here in one place”, says Dr. Falco Paepenmüller. This year, more than 1,000 customers from all over the world visited the EXPO.

Digital printing concept and VISTAFLEX II in Lengerich

The highlights of this year's EXPO were the live demonstration of the new digital printing concept and the rare opportunity to see W&H's largest machine, the VISTAFLEX II. With the VISTAFLEX II, W&H took advantage of the fact that the machine is about to be delivered to Bema, Inc. in the USA. The VISTAFLEX II also prints on flexible and thin materials at a high speed of up to 800 m/min. Thanks to the use of two robots, it can be changed over in just a few minutes, making it ideal for short job runs. Due to its size, it is suitable for particularly large formats over 2,200 mm.

Up to 7 inkjet and 4 flexo printing units are arranged around the central cylinder.

Hybrid approach combines flexo and inkjet

The demonstration of the digital printing machine concept was a crowd-puller. With the concept machine, which is scheduled to be launched in 2026, W&H will bring the first industrial scale digital printing machine for package printing to the market. The innovative approach combines digital and flexographic printing. Up to 7 inkjet and 4 flexo printing units are arranged around the central cylinder to provide a wide range of applications and flexibility.

“The fact that customers take the time to visit us during a busy trade fair is high praise – to the innovative power of our machines and to the teams who present them for four days with enthusiasm and technical expertise," says Dr. Witt.