70 years CI flexo printing - 70 years of leading innovations

The history of central impression flexo presses for flexible packaging starts in 1954 - 70 years ago now. First introduced by Windmöller & Hölscher in 1954, this innovation transformed the industry and became a cornerstone of packaging worldwide. What started as an idea has grown into a global standard, known for its versatility, efficiency and quality. We look at 70 years of CI technology, from past milestones to current and future developments.

The OLYMPIA 1275

70 years ago, in 1954, Windmöller & Hölscher built the first central impression flexo press, the OLYMPIA 1275, for a customer in the USA for printing on cellophane.

The OLYMPIA 736 FLEXOREX

Since the mid-1950s, central impression flexo presses have enabled high-quality printing. In recent decades, advancements and collaboration among industry stakeholders have perfected flexographic printing, making it the leading method for flexible material printing.

The "green machines" from W&H

Until the early 1990s, W&H’s 'green machines,' including the OLYMPIA series, dominated the market. About 400 machines were built and their reliability, durability and performance are still considered legendary today.

A peak into the production hall of Windmöller & Hölscher from the time of the green machines

The OLYMPIA STARFLEX

This machine marked the beginning of a new era in W&H design. A design that all machines since have followed.

the NOVOFLEX

The development of CI presses advanced significantly with the introduction of direct drive technology. W&H pioneered this leap in 1993 with the NOVOFLEX.

The MIRAFLEX

Nearly 900 MIRAFLEX I and II presses are in operation in more than 90 countries. It is the most successful CI flexo printing press ever built.

The team behind

In November 2023, the 850th machine in this series, a MIRAFLEX II, was successfully completed. Since 2008, the MIRAFLEX flexo press has delighted customers all over the world.

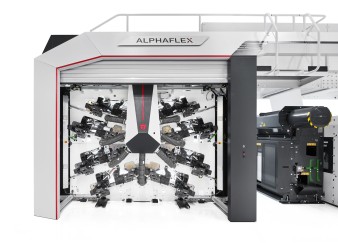

the ALPHAFLEX

The latest addition to the Windmöller and Hölscher CI flexo portfolio. The ALPHAFLEX, unveiled at drupa in 2024.

The future: Flexo meets digital

New digital printing concept for flexible packaging combines flexo and inkjet as a hybrid approach.