Improve your package printing with advanced print inspection

At a glance

Product information

Speed up your setup process

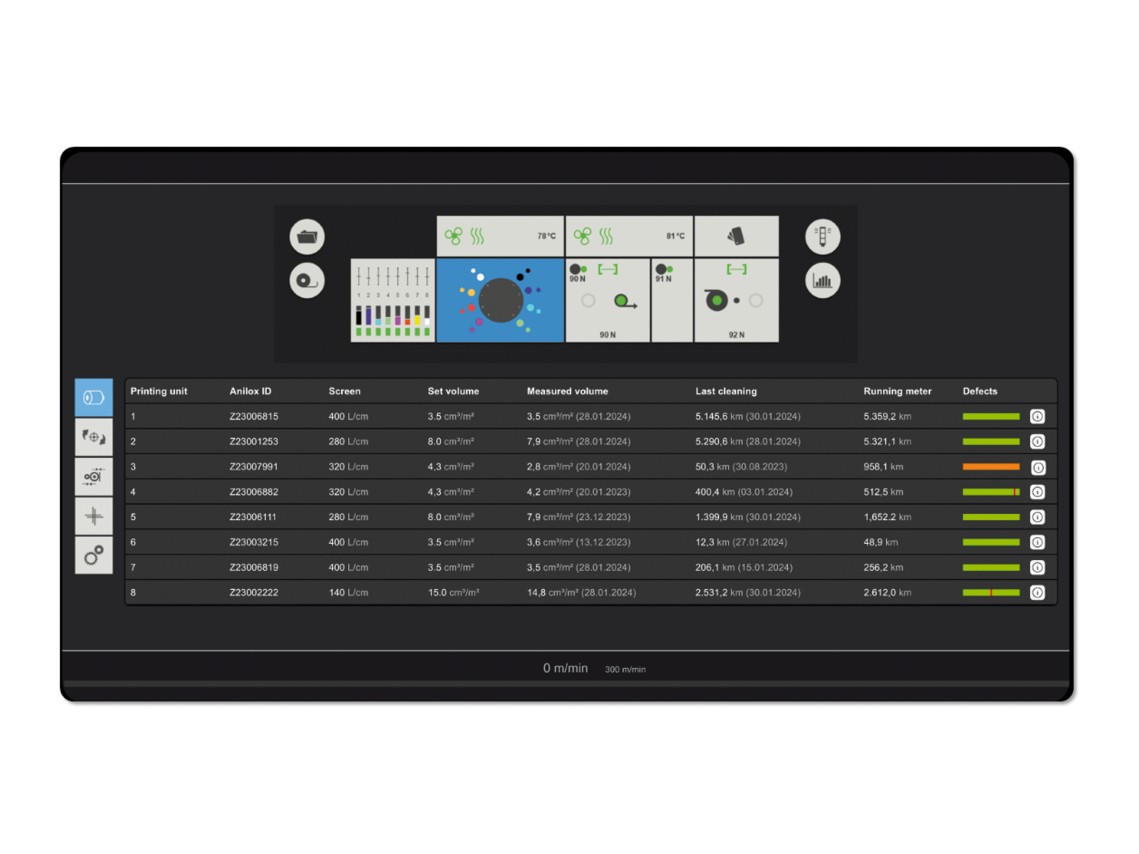

Can you see the actual condition of your anilox rollers? Which ones need cleaning? Which ones are defective? At first glance, all anilox rollers, even those with the same specifications, look the same. As a result, up to one in three jobs requires anilox roller replacement. This wastes time, ink, materials and money.

Stop gambling and use the RUBY Anilox smart tool management system! View the history of your anilox rollers and select the right anilox roller for your inking unit. Easily record your anilox data and digitize your manual processes: Automatically track your job-related running meters during production. Mark your anilox roller defects directly in PROCONTROL as they occur. Use your RUBY Anilox App to organize and record the volume measurements and cleaning of your anilox rollers based on their history.

Take advantage of your data while preparing your next print job: View real-time updated conditions of your anilox rollers in PROCONTROL or in your RUBY Anilox App and use our convenient features to directly define the right anilox rollers for your job. Speed up your set-up process and increase your efficiency by using RUBY Anilox.

Use cases with RUBY Anilox

1. Digitization of manuell processes

- Consistent and convenient documentation independent of the user supported by App and PROCONTROL.

- With VISION, you can easily document anilox roller defects in PROCONTROL as they occur.

- Organize cleanings of your anilox rollers based on their history at the right time and note the cleaning in the app.

2. Choose the right anilox roller

- Use our convenient functions to define directly the appropriate anilox rollers for your print job.

- Make your actions visible and use PROCONTROL to monitor the status of your installed anilox rollers.

- Use the same anilox rollers for repeat orders and ensure reliable, consistent quality.

3. Manage your anilox roller data-based

- Get the most out of your anilox roller by using it as long as possible on suitable jobs.

- You know the exact condition of your anilox rollers. This allows you to select the anilox roller that still meets your specific requirements.

- Based on your data, decide whether to overhaul or replace the anilox rollers.