Efficiency is green

Services for a Sustainable Production

At a time when sustainability and efficiency have never been more critical, the printing and extrusion industries face the challenge of meeting high ESG standards without compromising competitiveness.

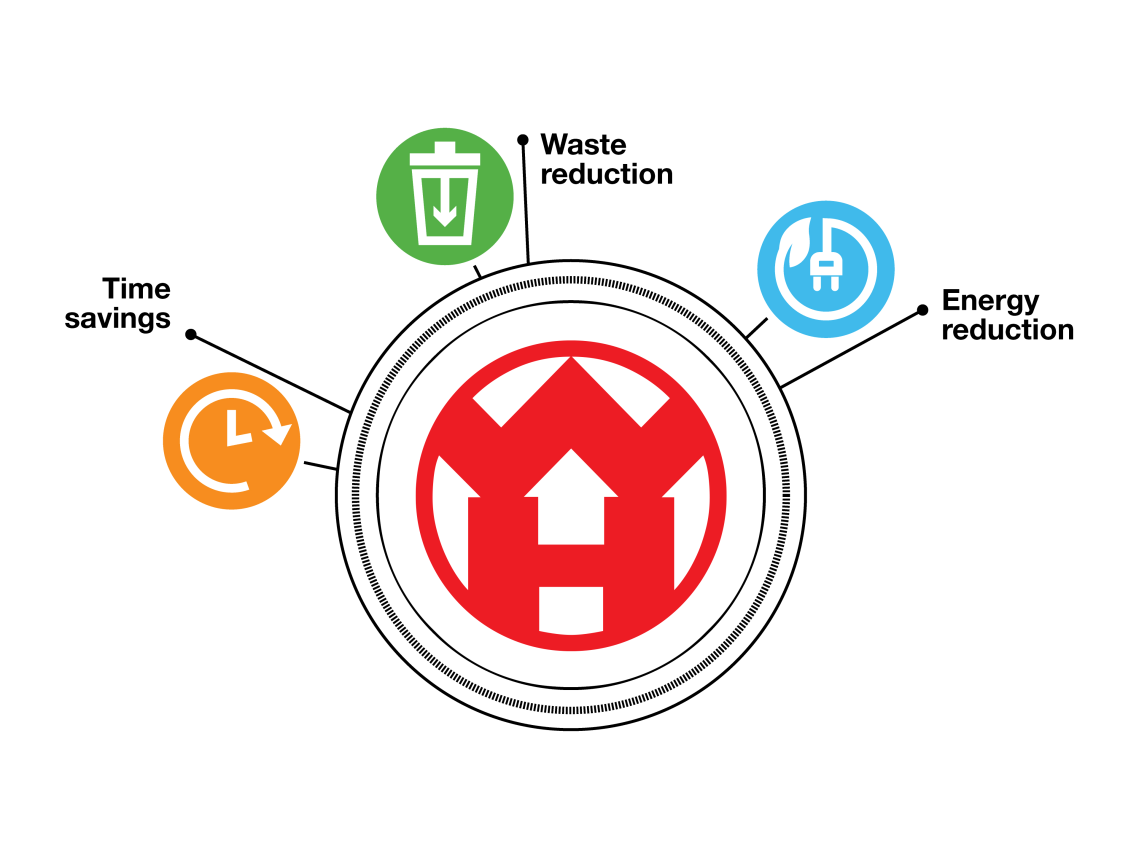

At W&H Services, we support you in reaching your sustainability and efficiency goals - not only with new machines, but by maximizing what’s possible with your existing equipment. Our comprehensive offering of retrofit solutions, lifecycle services, and customer trainings is designed to drive measurable improvements in three key areas:

- Time savings: By streamlining your workflows, accelerating setup and job changeovers, and reducing machine downtime, we enable efficient, time-saving processes that boost overall productivity and let you respond faster to changing customer demands.

- Waste reduction: Reduce material waste and production losses for more cost-effective and resource-efficient operations.

- Energy reduction: Cut energy consumption through optimized machine performance and intelligent process adjustments, helping both your bottom line and the environment.

Whether your focus is on printing or extrusion, our solutions empower you to make your production future-proof - more sustainable, more productive, more competitive.

Explore how W&H Services can help you achieve lasting improvements in your printing or extrusion processes:

Please choose whether you are interested in solutions for printing or extrusion.