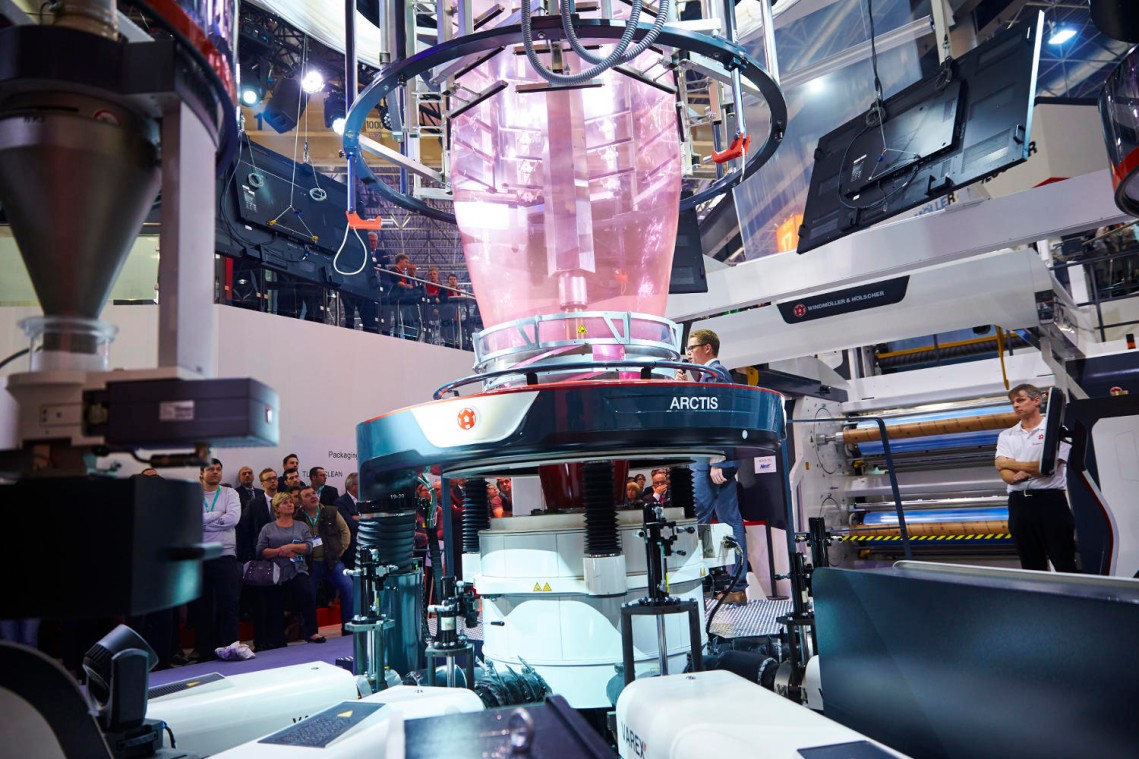

Stop and start blown film lines 50% faster

TURBOSTART is a new automation module for stopping and restarting blown film lines 50% faster, safer and easier.

Film manufacturers are continuously working on optimizing their machine utilization and film quality. "Starting and stopping a line leads to loss of time and quality fluctuations, but is unavoidable," explains Martin Backmann, Head of R&D Extrusion at W&H. According to the expert, film manufacturers stop and start their lines at least once a day, often even more, for example for cleaning and maintenance. "Our goal was a system that makes the process fast, safe and simple. TURBOSTART is the answer," says Backmann.

"A good operator needs at least 30 minutes to stop and restart a machine. With our automation the same process only takes 15 minutes”, says the R&D Manager. The work steps were designed to be as simple as possible. "The operator can activate TURBOSTART and control the process at the touch of a button on a screen of the PROCONTROL operating panel," says Backmann.

Manual work on the machine was automated to the greatest possible extent. Until now, in order to prevent quality problems caused by air inclusions, the operator had to cut the bubble with a knife at the top of the haul-off. This costs time and is a safety hazard. TURBOSTART takes over this work step fully automatically", Backmann gives an example.

"TURBOSTART enables every operator to stop and start the system efficiently and safely thanks to its simple handling and high level of automation. Due to the controlled process, the system is back in good production in a very short time," summarizes the engineer.