Your benefits at a glance

One Pager

All about Triplex full PE high barrier pouch

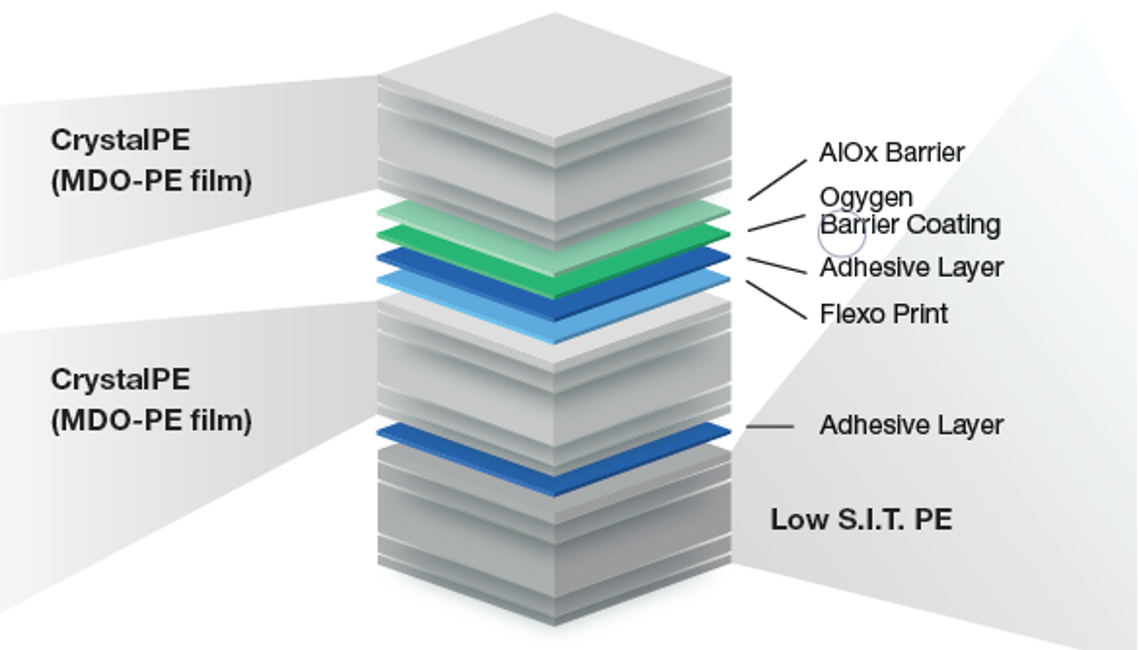

In cooperation with Nordmeccanica and Henkel, we have developeda highly stable pouch with a triplex laminate for demandingapplications. The barrier function is achieved with a transparentAlOx layer and an oxygen barrier coating, LOCTITE® LIOFOL® BC1582 RE from Henkel. Both layers were applied using NordmeccanicaVacuum & Coating technology (Nordmet 12 F Plus/SuperCombi 5000). This combination protects the AlOx layer andensures a high barrier function. The triplex pouch was laminatedwith Henkel's solvent-free, recyclable LOCTITE® LIOFOL® LA7818 RE/LA 6231 RE adhesive on Nordmeccanica's triplex oneshot laminator.

Our partners

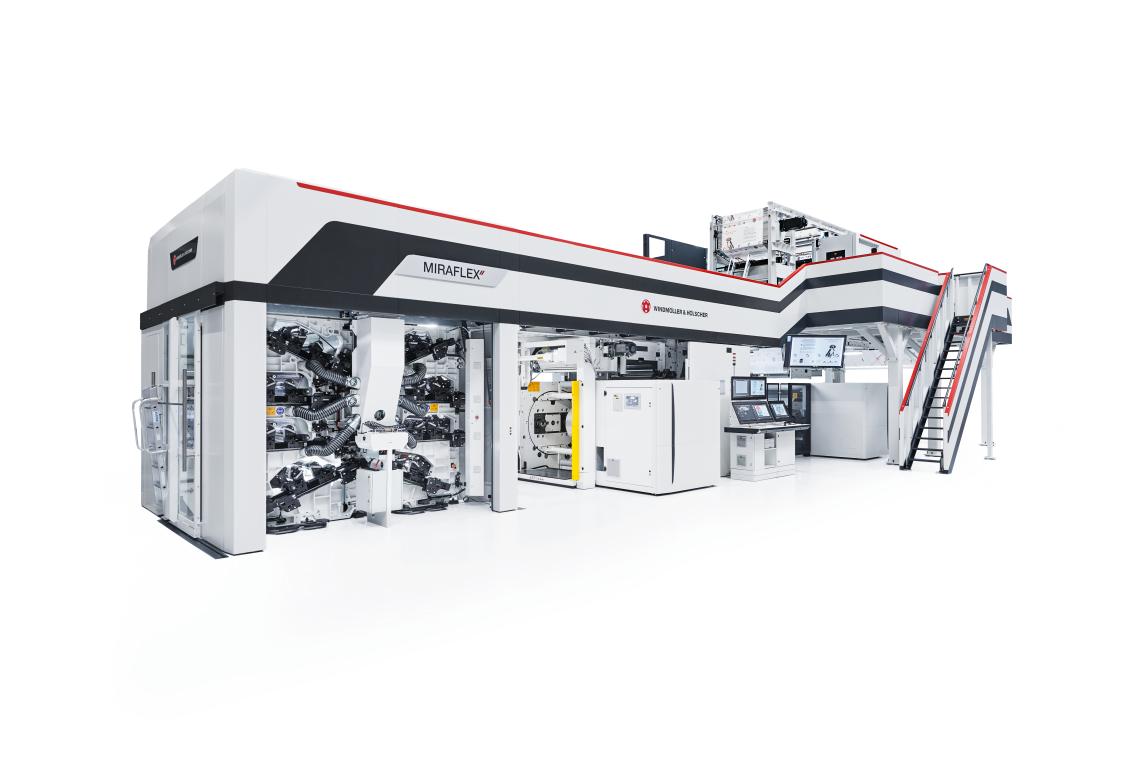

Why MIRAFLEX WITH INLINE PRINTING TECHNOLOGY?

Sustainable printing made easy – Printed barrier solutions

Freshness and quality are important, especially for packaged food products. To achieve these, the barrier properties of the packaging used are crucial. W&H has been working with various market leading partners to further develop barrier coating technology for packaging products as a sustainable and flexible alternative to multi-layer packaging material.

- Best print quality

The robust print deck design, drying capabilities and web handling are the base for the superior print quality of the MIRAFLEX´´

- Efficient inline processes

Choose between flexo and gravure inline solutions with high-capacity drying systems, especially forwater-based coatings. - Fast changeovers

Integrated EASY modules for impression and register setting allow quick, waste-minimizing set-up and job changes. TURBOCLEAN with diaphragm or electric pumps guarantees exceptional cleaning results and most efficient ink and solvent usage. W&H's approach on sustainable flexo production.