Your benefits at a glance

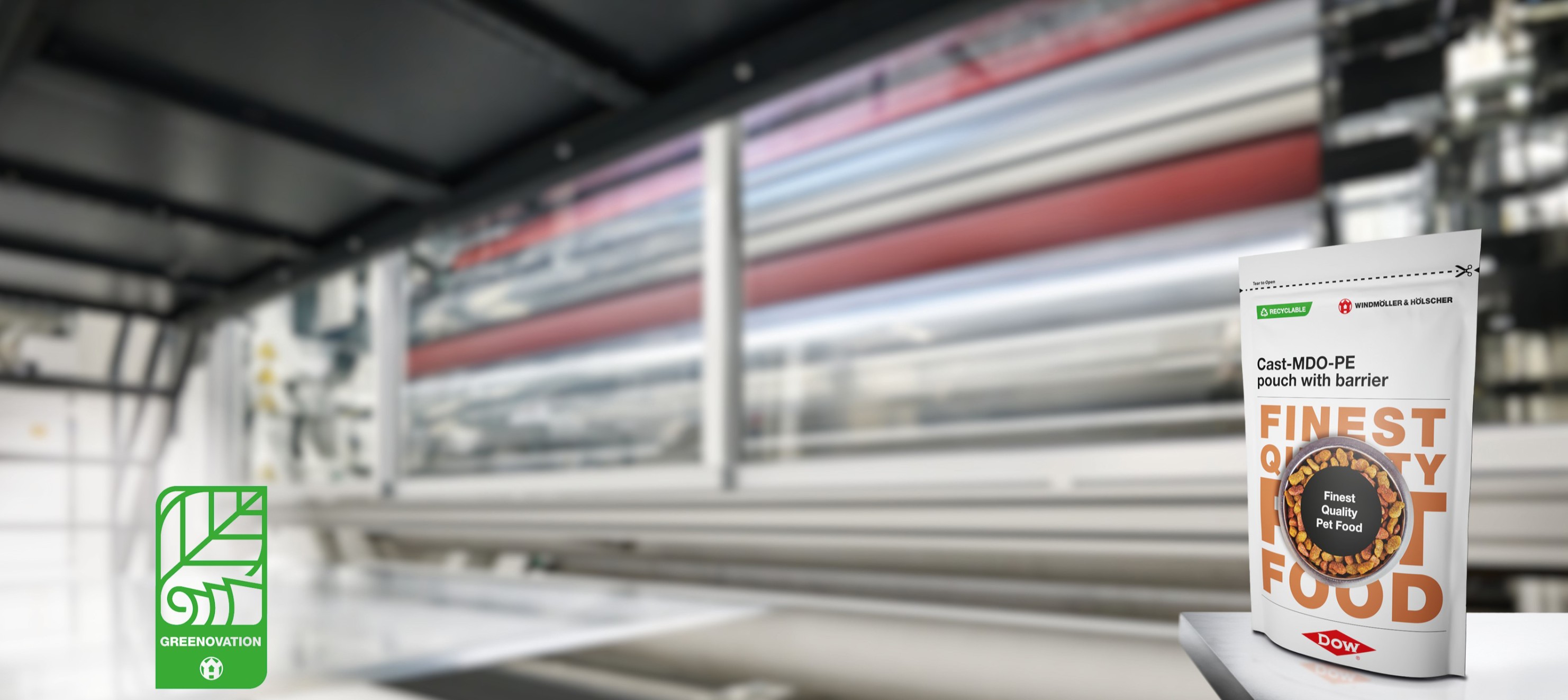

CAST MDO-PE POUCH WITH BARRIER

Our approach is designed to help you replace the PET

composites commonly used today with an environmentally

friendly solution.

This pouch is designed for recyclability, highest efficiency

and packaging performance:

- Mono-material MDO-PE film designed for printing

- Laminated against a PE-based sealing film containing

a thin layer of EVOH

PARTNERS

WHY FILMEX'' WITH MDO-L

The full integration of the MDO-L unit into the machine layout for ease of handling together with DCW profile control delivers a consistent superior film quality across the web width at top output rates.

Best-in-class extrusion equipment combined with our deep product and process know-how enables you to become a leader in sustainable film production.

- MDO-L special designed stretching unit with automatic gap adjustment for highest process stability and reduced neck-in

- MDO profile control with permanent automapping and assistance for a convenient operation ensuring an excellent film profile and consistent production

- DIE CONTROL WIZARD (DCW) touchless die operation for fast adjustments to ensure an efficient stretching process