At A glance

Product information

RUBY TRACK - Identify and utilize your hidden production potentials

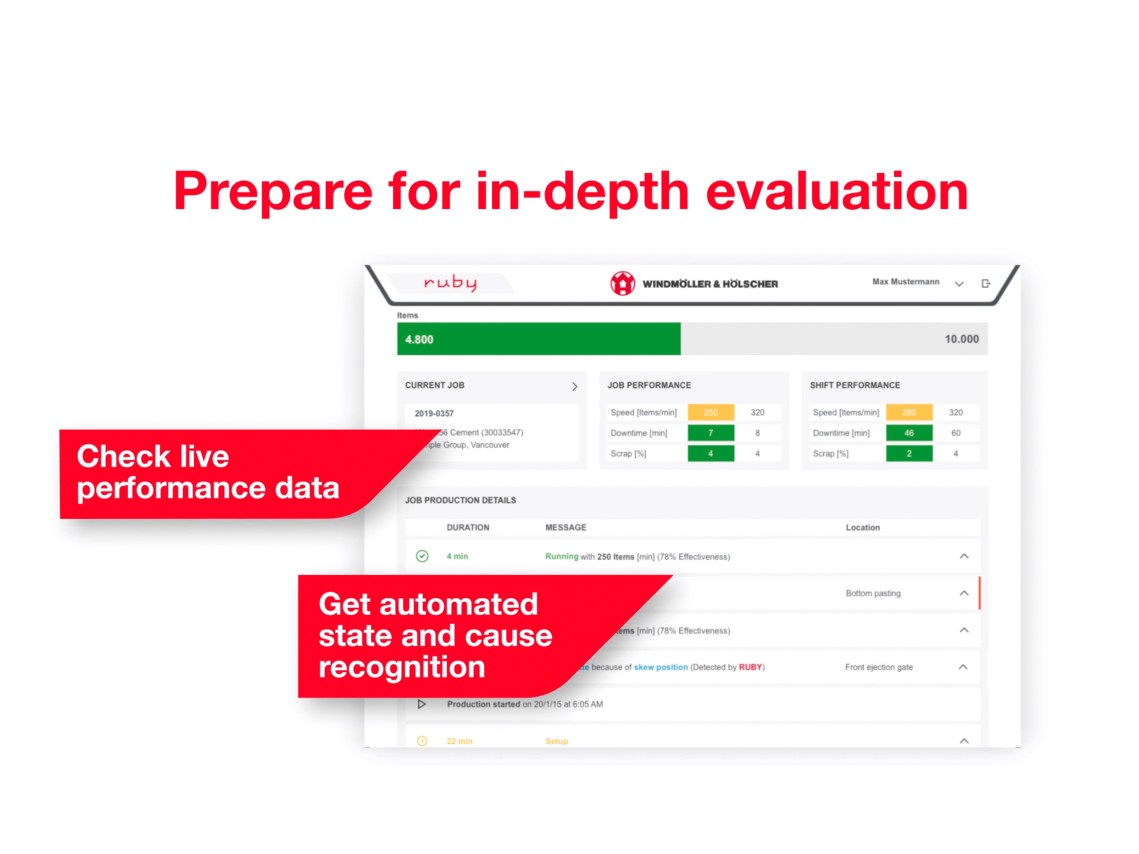

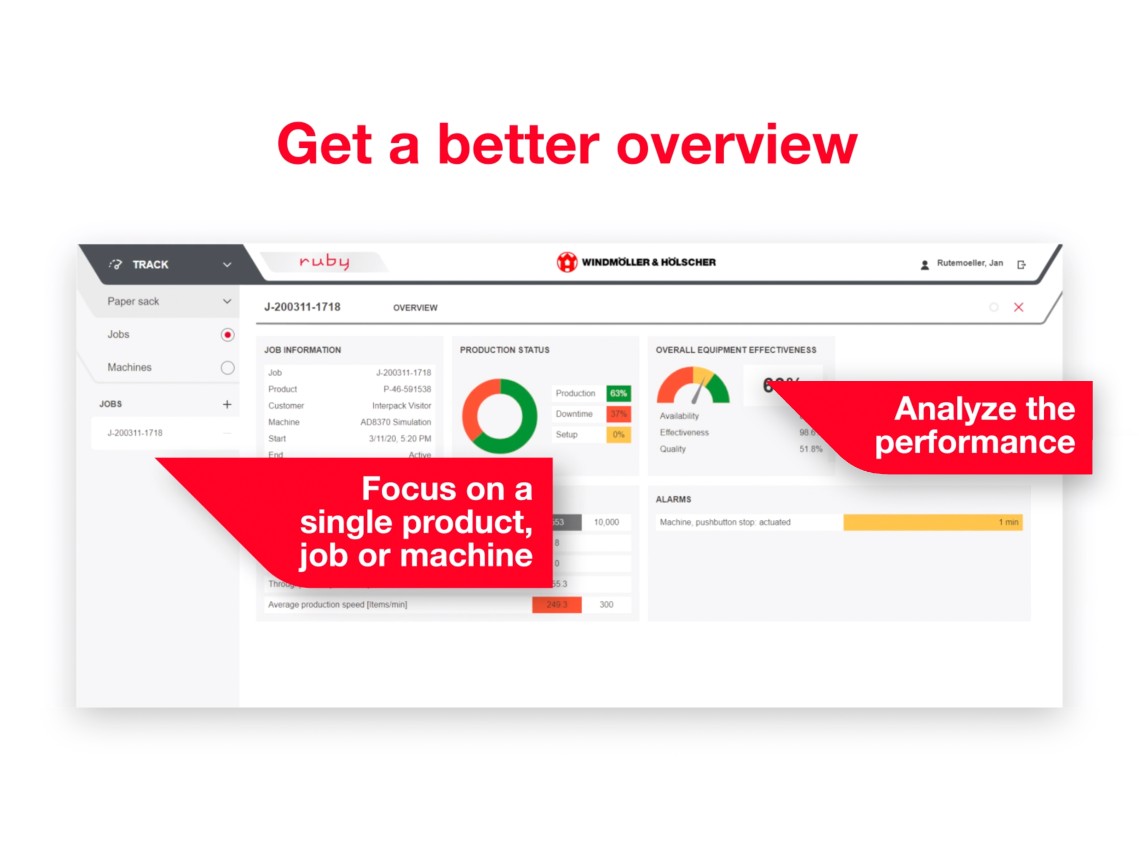

With the RUBY Track extension, decisions can be made based on meaningful analyses. You can rely on your production data, because with our W&H know-how most data is collected automatically.

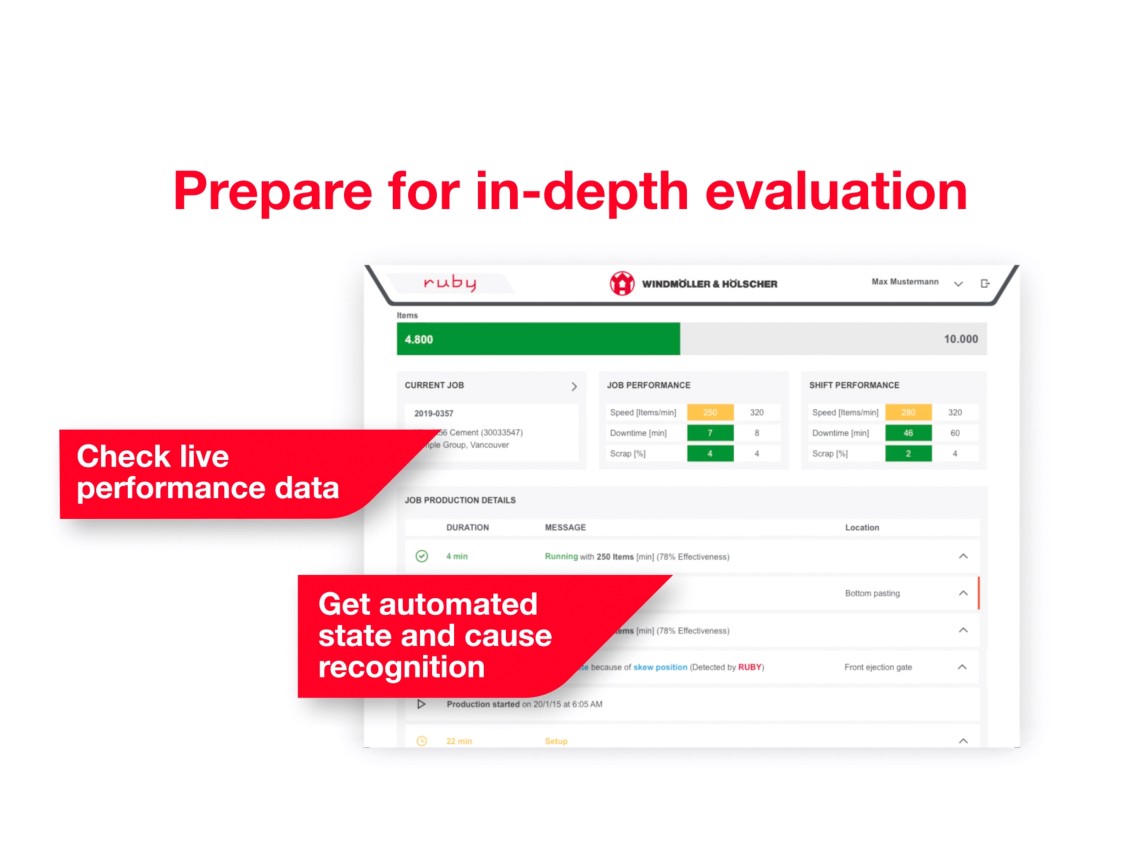

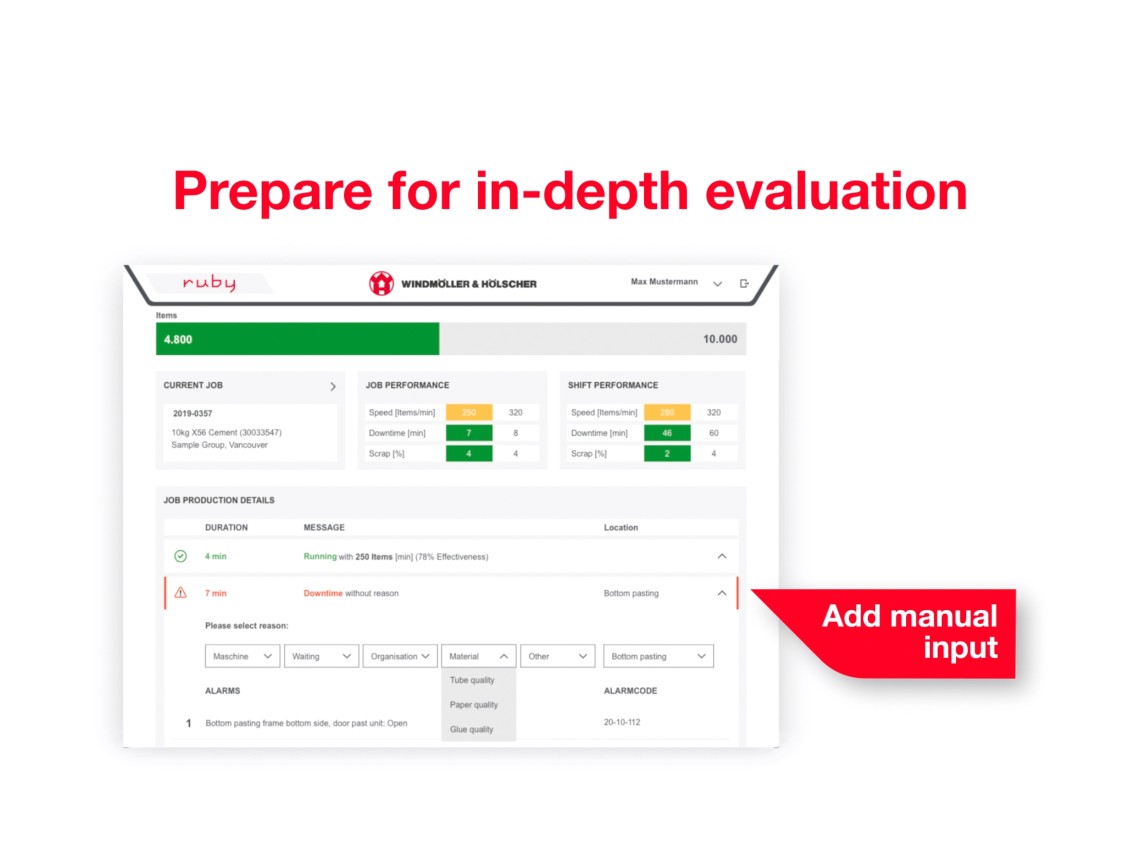

Previously subjective decisions with high impact on Overall Equipment Effectiveness (OEE) data, e.g. when did the job start and how long did the setup take, are replaced by data-based algorithms. In addition, machine stops can be differentiated into job-related and general downtimes, and many reasons for downtime can be recorded automatically. If operator input is required, it can be done with a few clicks.

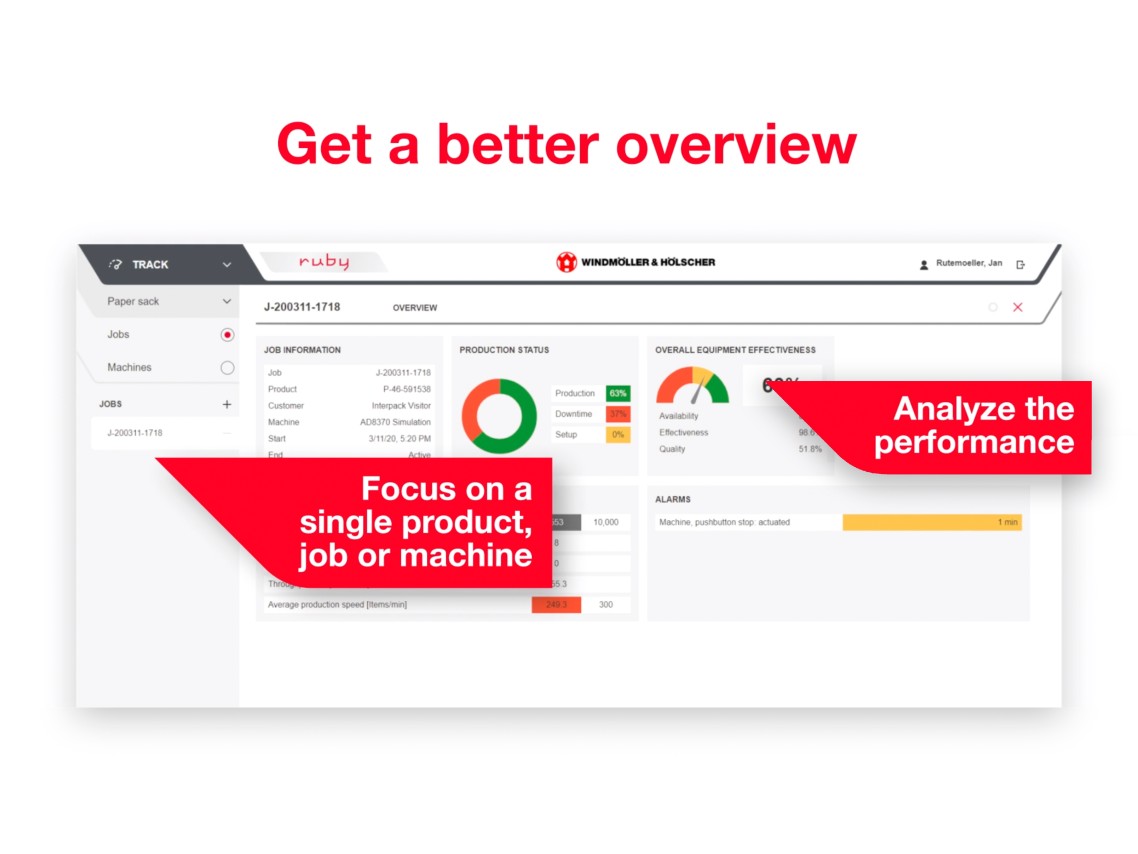

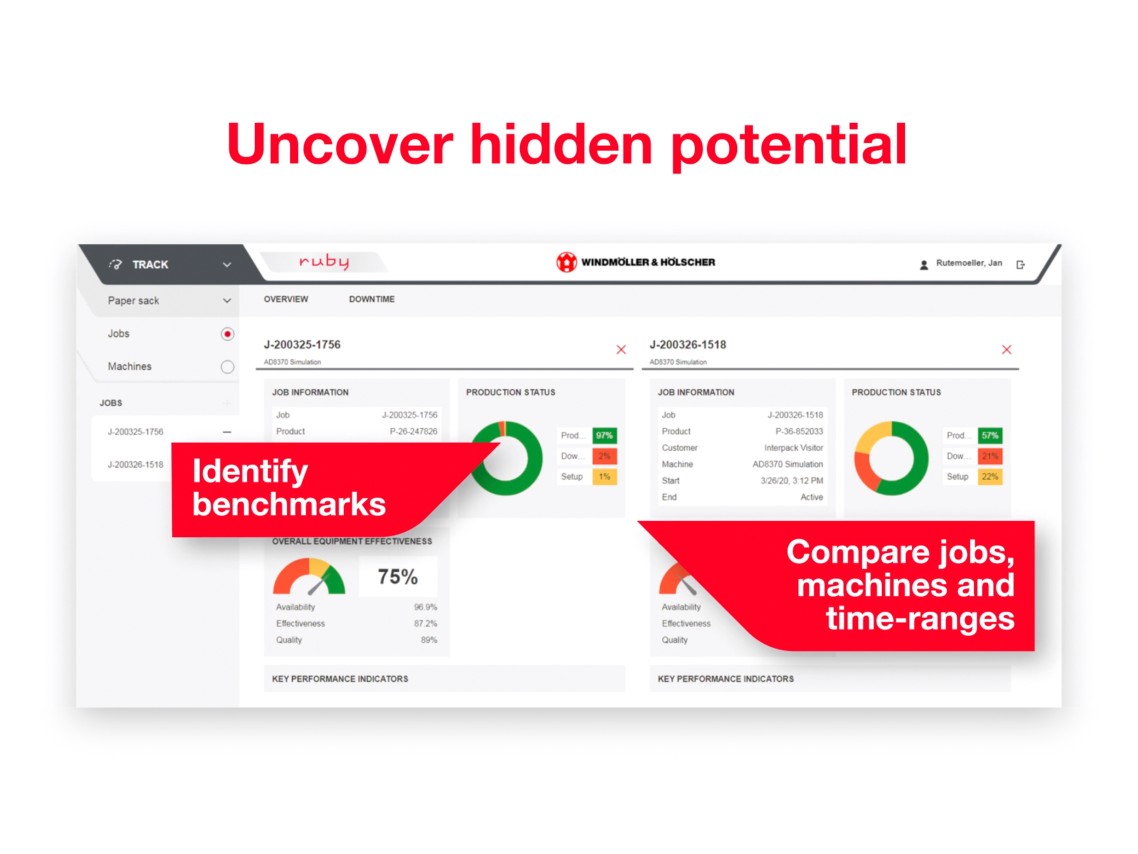

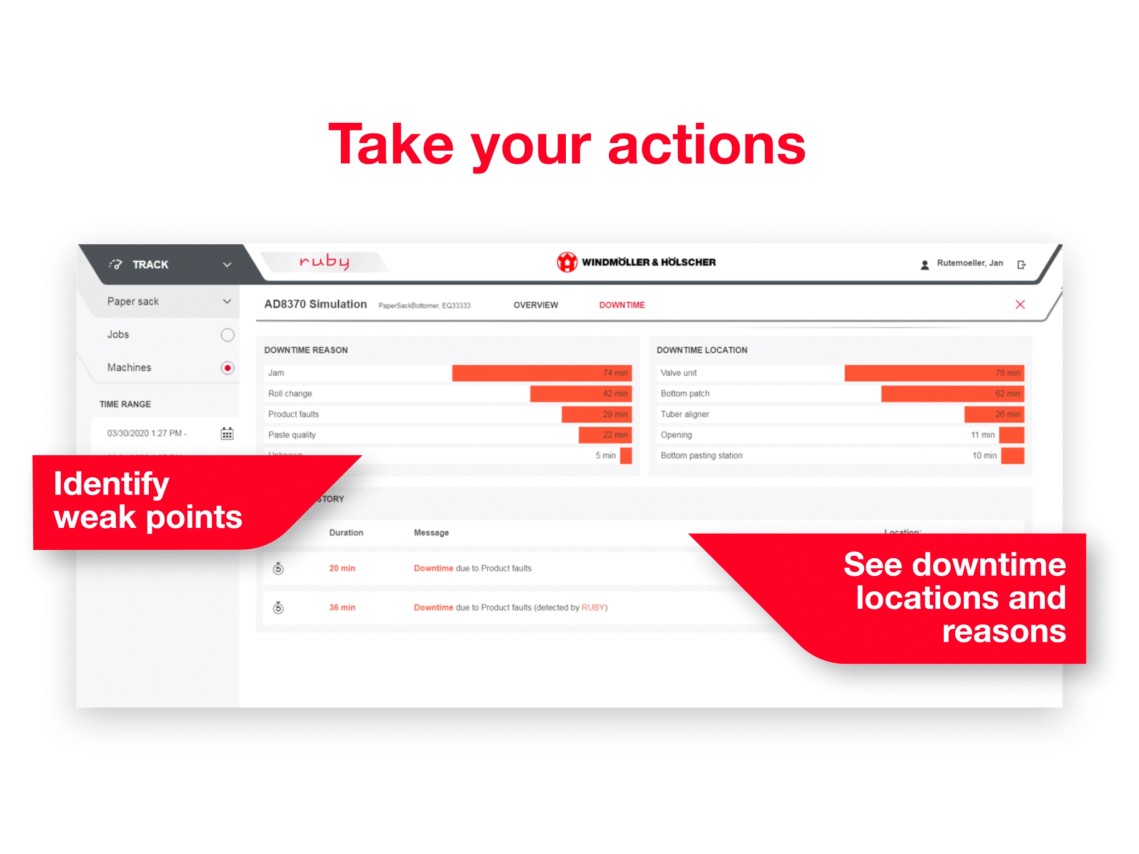

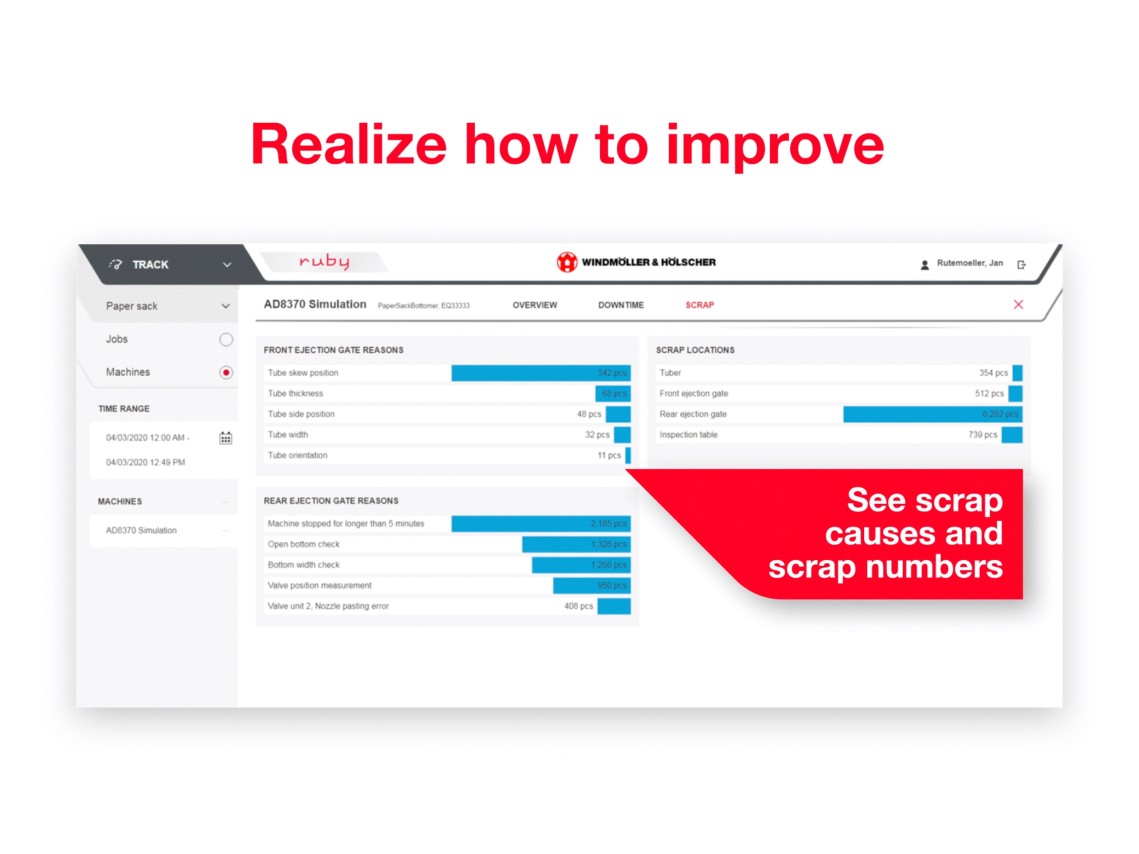

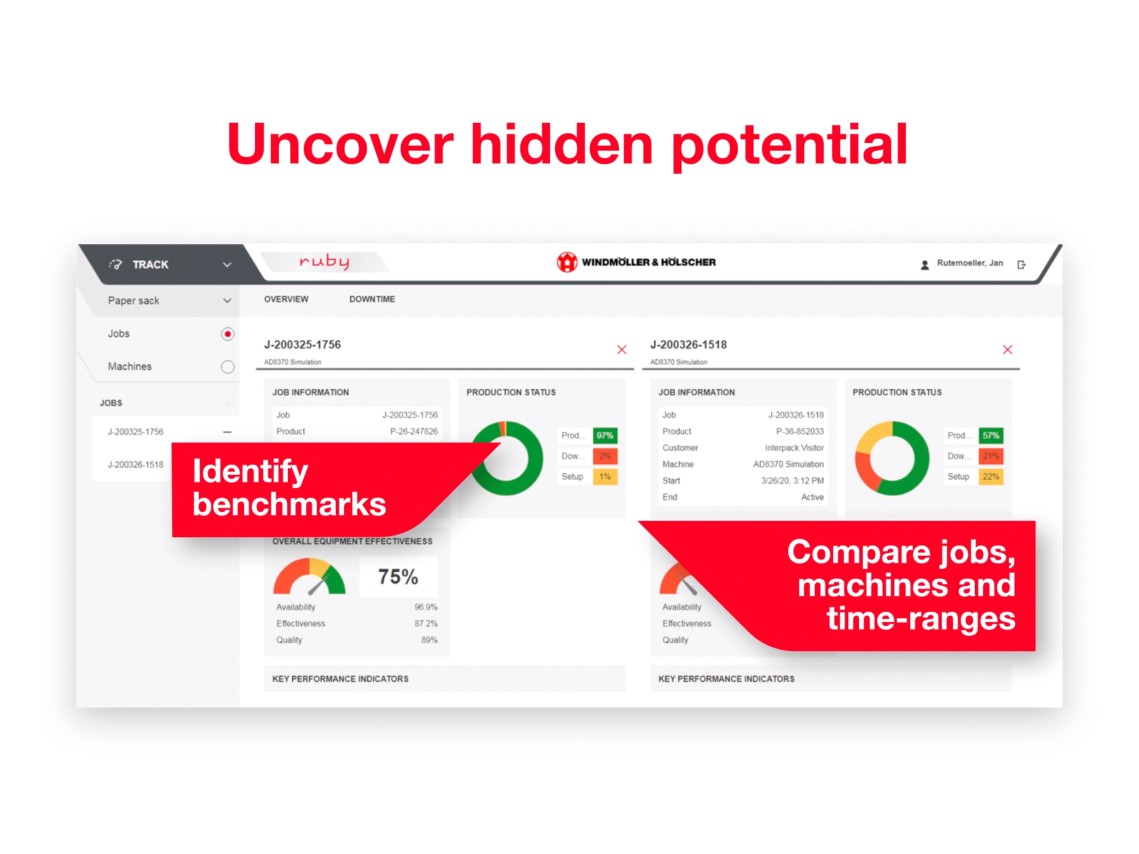

Get to know your benchmarks and weak points in the office interface: View and compare reliable job and machine KPI’s in a user-friendly web interface. Downtime and scrap analyses show you where you should have a closer look at. Furthermore, the benchmark feature allows you to identify your golden production runs and manage target speeds.

With RUBY Track, you know what actions are most effec-tive to increase the performance of your W&H Paper sack lines.

Get more out of your current production setup.

Use cases for RUBY Track

1. Smart Data Recording

- W&H know-how is used to record data automatically

- Operator interface allows to fill in reasons whenever the operator has got the time to do it

2. Transparency

- Modern, intuitive web interface to explore data

- Get performance KPIs

- Comparisons of jobs, machines, time ranges are done by just two clicks

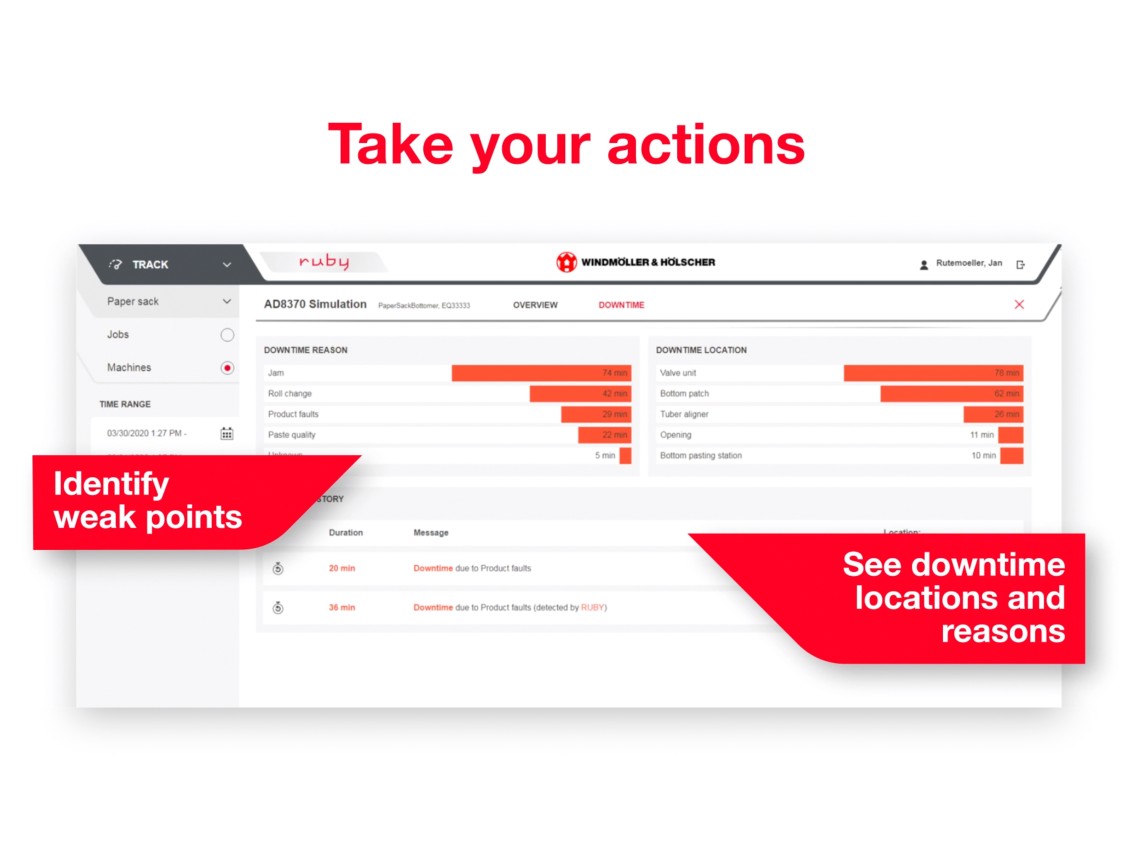

3. Downtime analysis

- Aggregated downtime reasons and locations are provided

- Identify your weak points

- Effective actions and measures can be derived

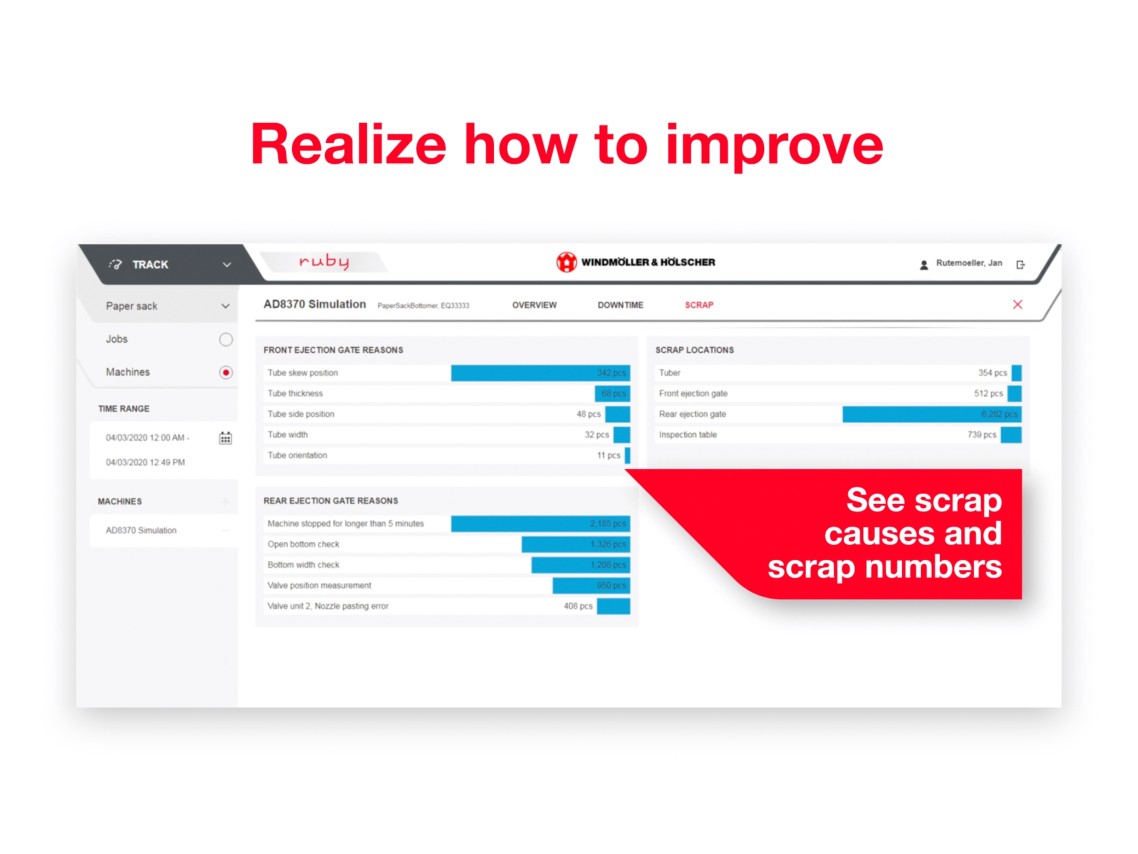

4. Scrap analysis

- Aggregated scrap reasons and locations are visualized

- Based on the numbers actions can be derived quickly and effectively

5. Benchmarking

- Identify ‘golden runs'

- Increase product specific target speeds

- Let low-performing operators learn from the experts