RETROFIT SOLUTIONS FOR W&H CONVERTING MACHINES

High efficiency, top quality and maximum flexibility at low prices - the market demands highest performance from flexible packaging manufacturers. However, investing in new machinery is not always the best solution to meet these requirements. With our retrofit solutions, new functions or modules can be added to existing converting machines. The development of customer-specific special solutions is also one of our core competencies. This enables you to react to new challenges at any time.

Our retrofit solutions address individual needs, such as:

- Quality improvement & monitoring

- Industry 4.0

- Process engineering

- Energy saving

- Cost reduction

- Operator friendliness

- Performance increase

- Occupational safety

CHOOSE FROM DIFFERENT RETROFIT SOLUTIONS FOR YOUR CONVERTING MACHINE

Inline FLEXA II (printer)

INSTALLATION

Approx. 10 days

Pre make ready „Eco Plus“ (printer)

INSTALLATION

Approx. 4 days

Sleeve Technology „Eco“ (printer)

INSTALLATION

Approx. 3 days

Enclosed doctor blade chamber (printer)

INSTALLATION

Approx. 1 day

Fountain roller to doctor blade chamber (printer)

INSTALLATION

Approx. 4 days

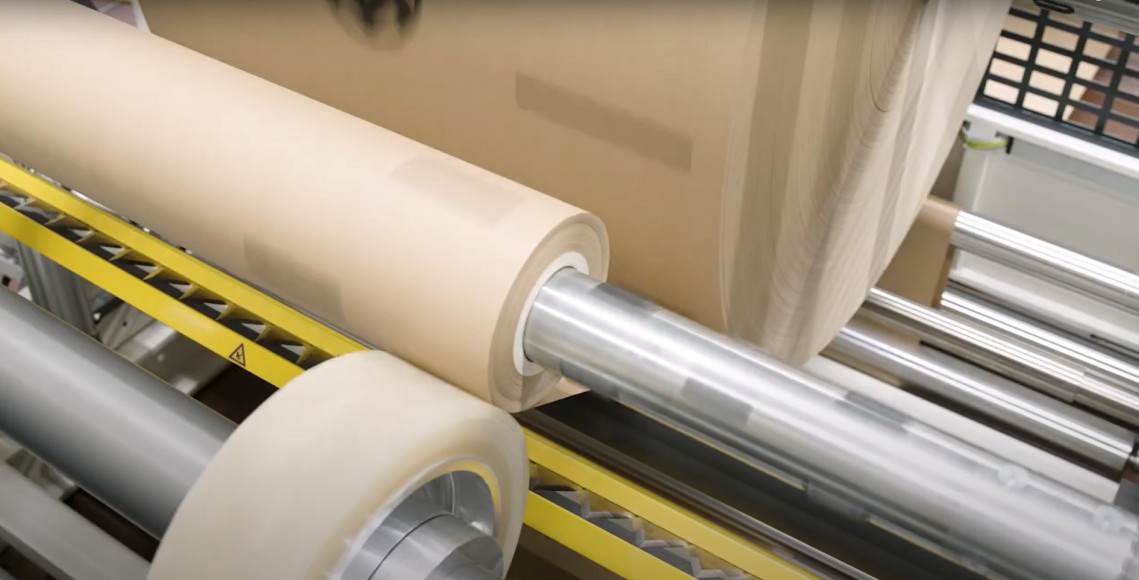

Non-stop Roll Change (tuber)

INSTALLATION

Approx. 4 days per unit

Venthole Perforation (tuber)

INSTALLATION

Approx. 2-3 days

Carrying Handle Unit (bottomer)

INSTALLATION

Approx. 1 day per unit

Easy Opening (bottomer)

INSTALLATION

Approx. 1 day per unit