At a glance

Product information

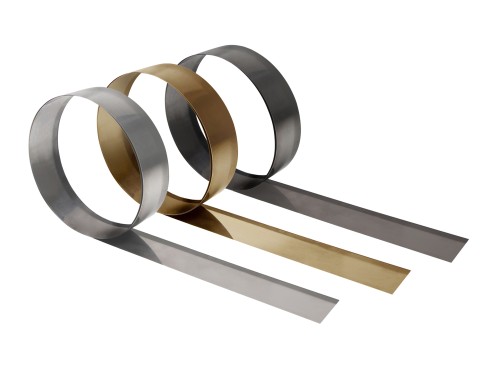

High-quality end seals specially designed for W&H machines

For optimum printing results it is essential to adapt the consumables to the printing press and the requirements of the printing process. The chamber end seals in particular have a significant impact on the efficient operation of the color decks.

Original chamber end seals from Windmöller & Hölscher are manufactured with the highest precision and are specially developed for use on our high-quality flexo printing presses. We use only qualified and high-performance materials, which also ensure the high requirements for mechanical explosion protection. This ensures safe operation of your printing press and, at the same time, optimum ink application without leakage. And that even at high printing speeds and long runtimes.

Our consumables portfolio includes a wide range of chamber end seals for various applications. This way, you are optimally equipped for all challenges in your daily production. Our product range includes not only seals for the current W&H machine portfolio, but also for older printing presses.

Technical Data

Chamber end seals for W&H printing machines: MIRAFLEX, MIRAFLEX II and VISTAFLEX

| Product name | Max. speed | Lifetime | Inking system |

| CSL 350 (soft) | 350 m/min | Medium | Solvent based inks |

| CSF 600 (medium hard) | 600 m/min | Medium | Water based inks |

| CSS 600 (soft) | 600 m/min | Medium | Solvent based inks |

| CSC 800 (medium hard) | 800 m/min | High | Solvent based inks Water based inks |

| CSE 1000 S (soft) | 1000 m/min | Extra high | Solvent based inks Water based inks |

| CSE 1000 H (hard) | 1000 m/min | Extra high | Solvent based inks Water based inks |

Original W&H Chamber End Seals

CSL 350

The W&H chamber end seal CSL 350 is suitable for the use of solvent-based inks.Depending on the application, it can be used up to a maximum printing speed of 350 m/min.

CSF 600

The W&H chamber end seal CSF 600 made of felt is especially suitable for the use of water-based inks. Depending on the application, it can be used up to a maximum printing speed of 600 m/min.

CSS 600

The W&H chamber end seal CSS 600 is suitable for the use of solvent-based inks. Thanks to its coated surface, it has increased sliding properties. This means that the CSS 600 can be used up to a maximum printing speed of 600 m/min, depending on the application.

CSC 800

The W&H chamber end seal CSC 800 is suitable for solvent-based inks and water-based inks. Thanks to its special material properties, it dampens vibrations and at the same time has a long lifetime and high sliding properties. Depending on the application, the CSC 800 can be used at printing speeds of up to 800 m/min.

CSE 1000 S

The W&H chamber end seal CSC 1000 S is suitable for solvent-based inks as well as for water-based inks. Thanks to its special material properties, it has a very long lifetime as well as very high sliding properties. Depending on the application, it can be used up to a maximum printing speed of 1000 m/min.

CSE 1000 H

The CSE 1000 H is suitable for solvent-based inks and water-based inks. Thanks to its special material properties, it dampens vibrations and at the same time has a very long lifetime as well as very high sliding properties. Depending on the application, the CSE 1000 H can be used up to a maximum printing speed of 1000 m/min.

Individual advice

To ensure that you use the most efficient consumables for your needs, we will be happy to advise you personally. Simply contact your local sales manager or get in touch with our experts directly: consumables@wuh-group.com

Our advice includes:

- In-depth expert analysis with reference to your machine, jobs,

quality and productivity - Identification of open potentials

- Compilation of an optimally harmonized consumables package

- Optimization of machine settings and the printing process

- Tips for professional machine operation

- Support with printing and production-related questions

- Improvement of productivity and product quality